© 2025 Messer Cutting Systems, Inc.

In today's rapidly evolving manufacturing landscape, Laser Cutting Services have emerged as a game-changer, revolutionizing how industries approach precision cutting and fabrication. According to a report by Research and Markets, the global laser cutting market is projected to reach $5.7 billion by 2026, driven by increased automation and demand for high-quality, intricate designs. These services leverage advanced technology to deliver unparalleled accuracy and efficiency, with capabilities that span various materials including metals, wood, and plastics. As businesses continue to seek innovative solutions to enhance production processes, understanding the incredible advantages and applications of laser cutting is crucial. This article delves into ten remarkable facts about laser cutting services that highlight their significance and transformative impact across multiple sectors.

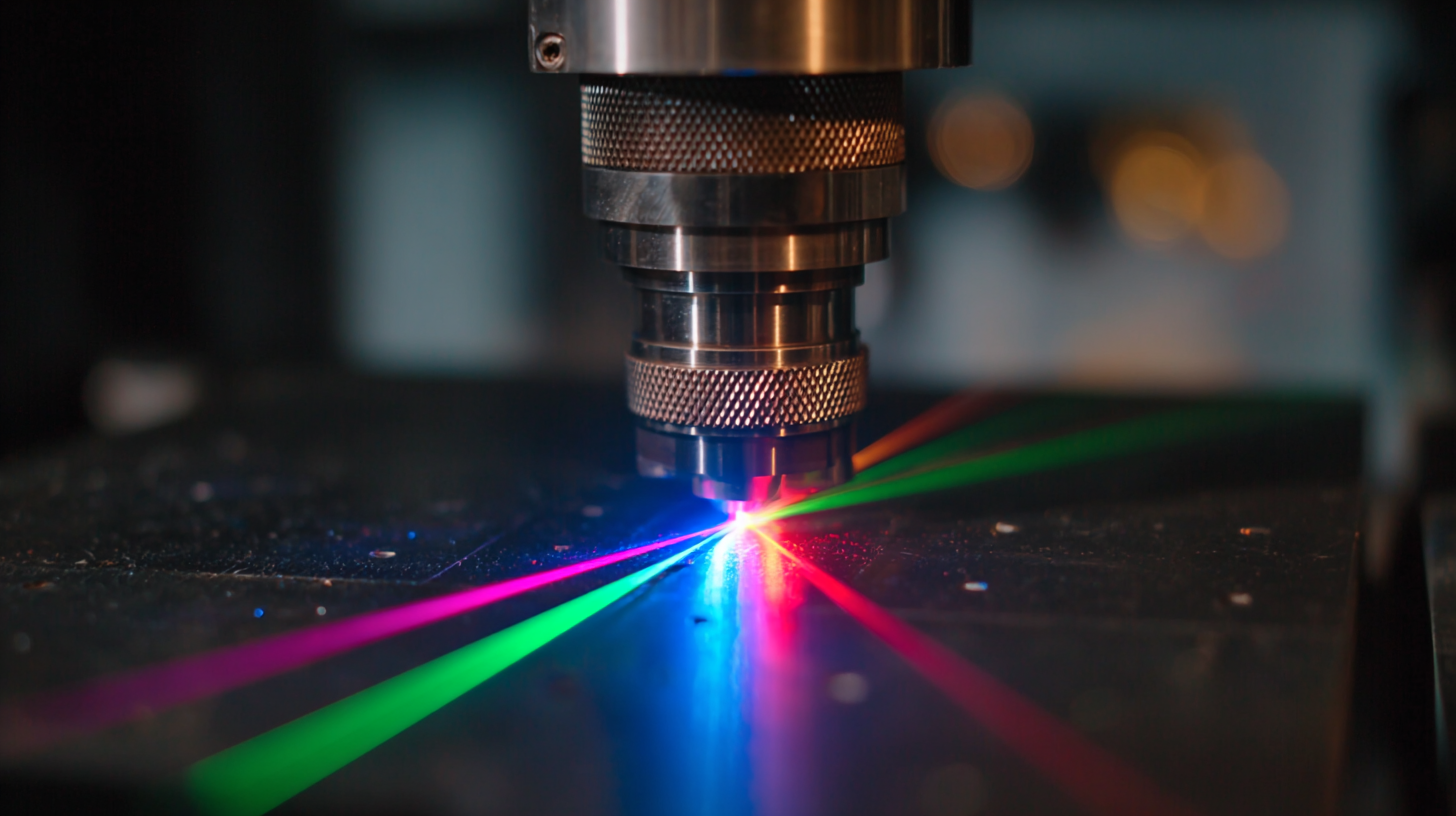

Laser cutting technology has revolutionized the manufacturing industry by providing precision and efficiency that traditional methods cannot match. Utilizing a focused beam of light, laser cutting can slice through materials with an accuracy of up to ±0.01 mm, making it ideal for intricate designs and detailed patterns. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $6.34 billion by 2024, driven by advancements in laser technology and increasing demand for precision cutting across various sectors.

One of the remarkable aspects of laser cutting is its versatility; it can be applied to a wide range of materials, including metals, plastics, wood, and fabrics. A survey conducted by the Manufacturing Technologist Association found that over 70% of manufacturers are now integrating laser cutting into their production processes due to its ability to enhance speed and reduce waste. This technology not only reduces the need for additional machining but also minimizes material loss by up to 30%, significantly contributing to sustainability efforts in manufacturing. As industries continue to embrace innovative technologies, understanding the mechanics and benefits of laser cutting becomes essential for those looking to stay competitive.

Laser cutting technology has rapidly transformed numerous industries by providing a versatile and precise method of fabricating complex components. The application of laser cutting spans the aerospace, medical, electronics, and automotive sectors, where the demand for high-precision parts continues to grow. According to a recent market report, the precision parts market is expected to see significant expansion, driven by the accelerated adoption of laser cutting and other advanced manufacturing processes like CNC machining and electrical discharge machining.

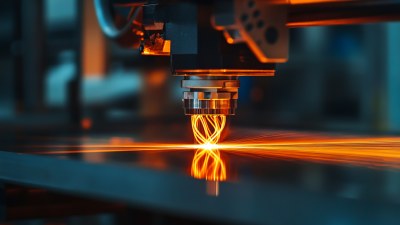

In the automotive sector, for instance, laser cutting has become essential in optimizing production and enhancing the quality of vehicle components. The technology supports various processes, including body welding and lightweight structure fabrication, which are critical for meeting modern performance and efficiency standards. Recent advancements in laser technology, such as the emergence of high-power fiber lasers, have enabled manufacturers to achieve deeper cuts and finer details, further enhancing operational capabilities.

The demand for laser cutting solutions is underscored by a projected growth in the global laser lighting market, which is anticipated to expand across industrial and healthcare applications by 2032. This growth reflects the industry's ongoing strategic shift towards automation and precision, facilitated by innovative laser technologies. Thus, the versatility of laser cutting services positions them as a crucial element in driving manufacturing efficiency and enhancing product quality across diverse industries.

This chart illustrates the versatility of laser cutting services by showcasing the common materials utilized in the laser cutting process across various industries.

Laser cutting services have become increasingly popular due to their exceptional cost-effectiveness, making them an attractive option for businesses across various industries. One of the primary ways these services save money is through reduced material waste. Laser cutting is known for its precision, allowing manufacturers to maximize the use of materials by achieving intricate designs and clean cuts. This minimizes excess material that would typically be discarded in traditional cutting methods, leading to significant savings over time.

In addition to material savings, laser cutting services also save time. The speed at which lasers operate means that tasks can be completed much faster than with manual cutting tools. This efficiency translates into shorter production times and quicker turnaround for projects, ultimately boosting productivity. Companies can take on more orders within the same timeframe, leading to increased revenue and a stronger competitive edge in the market. By investing in laser cutting services, businesses not only streamline their operations but also optimize their profitability while delivering high-quality products to their customers.

Laser cutting services have gained popularity not only for their precision and efficiency but also for their positive environmental impact. Unlike traditional cutting methods that produce significant waste and require extensive finishing processes, laser cutting is highly efficient and generates minimal scrap material. This reduction in waste is essential as industries aim to adopt more sustainable practices, making laser cutting a viable option for environmentally conscious businesses.

Furthermore, laser cutting utilizes energy more effectively than conventional methods. The focused laser beams can cut through various materials with less energy expenditure, leading to lower carbon emissions during production. Additionally, many laser cutting techniques use clean energy sources, further contributing to a reduced ecological footprint. As companies seek to align their operations with green initiatives, the adoption of laser cutting services stands out as not only a technological advancement but also a crucial step towards sustainability in manufacturing.

Laser cutting has revolutionized the manufacturing industry, providing unprecedented quality and precision in various applications. One of the standout features of laser cutting services is their ability to deliver intricate designs with remarkable accuracy. The focused laser beam can cut through a variety of materials—including metals, plastics, and wood—while maintaining tight tolerances that traditional cutting methods simply can’t achieve. This results in smooth, clean edges, minimizing the need for extensive finishing processes.

When considering laser cutting services, it’s essential to choose the right provider to ensure exceptional results. **Tip:** Always ask for samples of previous work to gauge the quality of their cuts and designs. Additionally, confirm that they use modern laser technology, as advancements in this field can significantly enhance the precision of the cuts.

Another key advantage of laser cutting is its versatility. It can be used for both small-scale projects and large production runs without compromising on quality. **Tip:** Communicate your specific needs clearly to your service provider; this ensures that they can adjust settings and techniques to match your project's requirements, enhancing the final outcome and saving time and resources. By understanding these factors, you can make informed choices that lead to superior finished products.

| Fact No. | Fact | Benefit |

|---|---|---|

| 1 | Highly Accurate Cuts | Ensures precision and reduces material waste. |

| 2 | Versatile Material Processing | Can cut through metal, wood, acrylic, and more. |

| 3 | Minimal Heat Affected Zone | Reduces the chance of warping or damaging material. |

| 4 | Complex Shapes and Designs | Allows for intricate designs that would be difficult to achieve with traditional methods. |

| 5 | Quick Turnaround Times | Increases production speed significantly. |

| 6 | Consistency | Delivers uniform results across multiple pieces. |

| 7 | Reduced Labor Costs | Less manual intervention required in the cutting process. |

| 8 | Eco-Friendly Process | Creates less waste compared to traditional cutting methods. |

| 9 | Automation Capabilities | Integration with CAD software for easier design implementation. |

| 10 | Safety Features | Advanced laser systems include built-in safety measures to protect operators. |

© 2025 Messer Cutting Systems, Inc.