© 2025 Messer Cutting Systems, Inc.

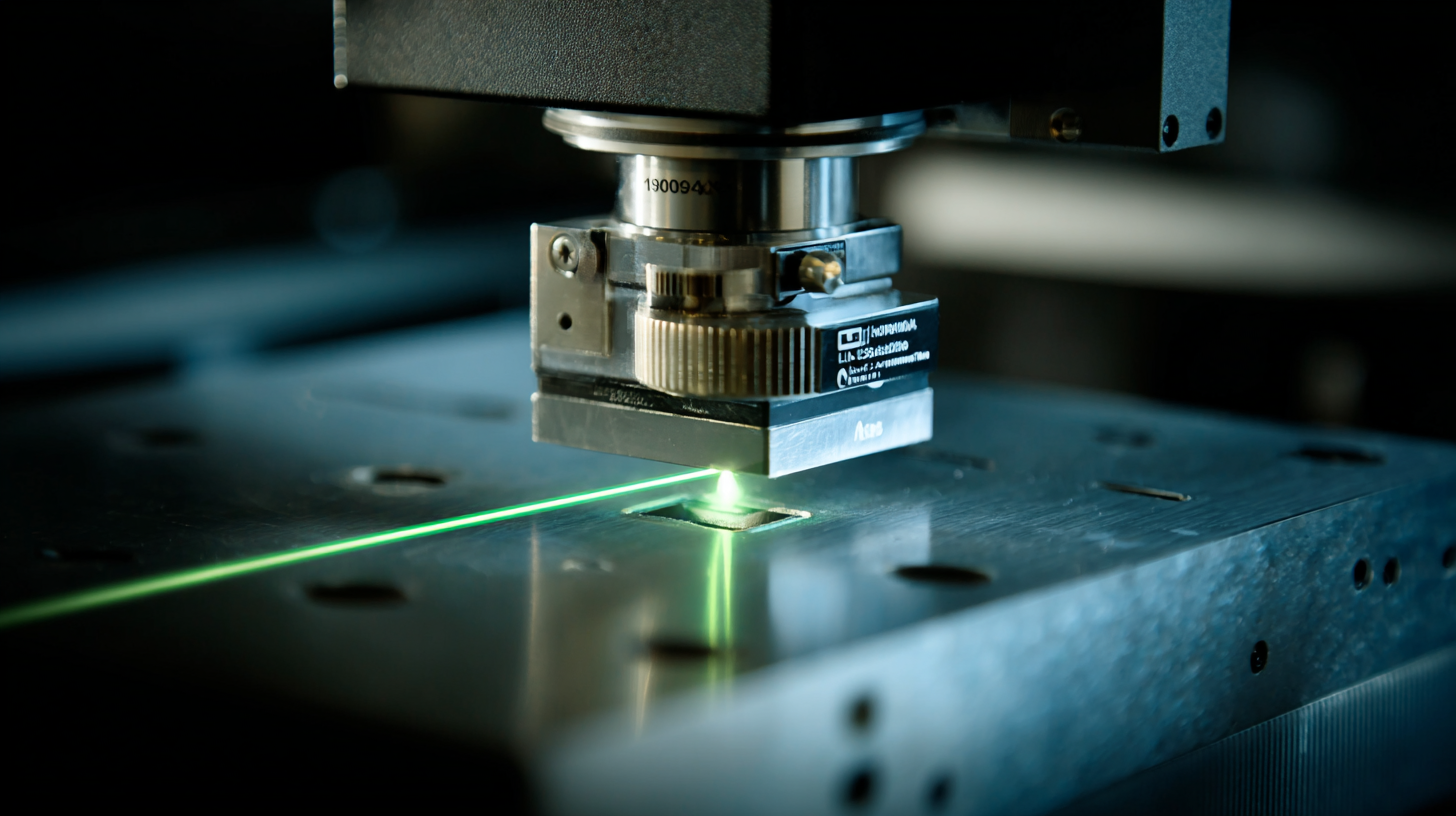

In the rapidly evolving landscape of manufacturing and material processing, the introduction of advanced Fiber Laser systems marks a transformative leap toward precision and efficiency. These cutting-edge technologies have not only revolutionized traditional applications but have also enabled industries to explore innovative techniques that enhance productivity and product quality. This blog delves into the technical specifications of the most advanced Fiber Laser systems currently available, showcasing their practical applications across various sectors.

In the rapidly evolving landscape of manufacturing and material processing, the introduction of advanced Fiber Laser systems marks a transformative leap toward precision and efficiency. These cutting-edge technologies have not only revolutionized traditional applications but have also enabled industries to explore innovative techniques that enhance productivity and product quality. This blog delves into the technical specifications of the most advanced Fiber Laser systems currently available, showcasing their practical applications across various sectors.

From automotive manufacturing to aerospace engineering, we will highlight industry case studies that exemplify the remarkable capabilities of Fiber Lasers. Additionally, we will provide a guide on how to effectively implement these systems within your operations, ensuring you stay at the forefront of technological advancements in laser processing.

The field of fiber laser technology is rapidly evolving, with innovations emerging beyond mainstream applications. Alternative fiber laser technologies are gaining traction due to their specialized capabilities and efficiency. For instance, according to a recent report by MarketsandMarkets, the fiber laser market is projected to reach USD 3.7 billion by 2024, growing at a CAGR of 6.7%. This growth is attributed to advancements in unique fiber laser configurations, such as aberration-corrected fiber lasers, which enhance beam quality and are particularly beneficial for high-precision cutting and welding applications.

Moreover, industrial sectors are beginning to adopt ytterbium and thulium-doped fiber lasers for niche applications. These lasers offer exceptional performance in areas requiring higher output power and specific wavelength ranges. A study by ResearchAndMarkets highlighted that the adoption of thulium fiber lasers in medical applications is expected to witness significant growth, driven by their efficiency in minimally invasive procedures. As we explore these alternative technologies, it becomes evident that the future of fiber lasers lies in diversifying their applications and enhancing their performance for specialized industrial needs.

When exploring the realm of advanced fiber laser systems, several key technical specifications stand out, shaping the performance and versatility of these tools.

First, the wavelength of the laser plays a crucial role in its application range. Typically, fiber lasers operate at wavelengths between 1060 nm and 1550 nm, providing excellent absorption rates in various materials. This wavelength flexibility makes them suitable for tasks such as cutting, welding, and engraving diverse substrates.

Tips: When selecting a fiber laser system, consider the materials you will work with and choose a wavelength that optimizes performance for those specific applications.

Another critical specification is the power output, typically ranging from a few watts to several kilowatts. Higher power levels increase cutting speeds and productivity but may also necessitate sophisticated cooling systems to prevent heat buildup. Notably, the beam quality, often expressed as a parameter called M2, indicates how well the laser beam can focus. A lower M2 value signifies a better beam quality, enhancing precision in laser processing.

Tips: Always evaluate the trade-off between power output and beam quality to ensure you achieve the desired precision and efficiency for your projects.

As industries increasingly seek efficient and high-precision solutions, fiber laser systems have emerged as a powerful tool across various sectors. From manufacturing to medical applications, these advanced systems present distinct advantages over traditional laser technologies. A comparative analysis reveals that fiber lasers generally offer superior beam quality, enhanced cutting speeds, and lower operational costs, making them a preferred choice for tasks such as metal cutting, welding, and engraving.

In the automotive industry, for instance, fiber lasers facilitate intricate cuts that are crucial for producing complex components with tight tolerances. Similarly, in the medical field, fiber lasers are utilized for minimally invasive surgeries, providing precision while minimizing damage to surrounding tissues. This versatility underscores the adaptability of fiber laser systems, positioning them as indispensable tools across diverse applications. As companies evaluate their technological options, the decision to adopt fiber laser solutions is often driven by the desire for greater efficiency, reduced downtime, and improved overall productivity. This competitive edge not only enhances operational performance but also aligns with the growing emphasis on sustainability in production processes.

The landscape of fiber laser technology is rapidly evolving, showcasing innovative features that significantly enhance industrial applications. Non-traditional fiber lasers stand out with their exceptional capabilities, offering unparalleled precision and efficiency in manufacturing processes. These advanced systems utilize breakthrough innovations in laser design and materials, enabling faster cutting speeds and improved energy consumption. The recent advancements in fiber laser technology empower industries to achieve high-quality results while reducing operational costs.

One of the most exciting aspects of these innovative fiber laser systems is their versatility across various applications. From photoacoustic microscopy to cutting-edge garment manufacturing, non-traditional fiber lasers are redefining traditional methods. Their ability to perform intricate tasks with minimal disruption makes them ideal for sectors that require meticulous attention to detail. Additionally, their non-invasive nature offers a significant advantage in achieving desired outcomes without damaging sensitive materials. As industries seek sustainable and efficient solutions, the integration of innovative fiber laser technology is paving the way for a more productive future.

This chart illustrates the specifications of the latest advanced fiber laser systems, highlighting the output power, beam quality, cooling method, efficiency, and wavelength. Each feature plays a crucial role in defining the performance and application of fiber lasers in various industries.

The landscape of fiber laser technology is continually evolving, with future trends poised to redefine its applications across various industries. One of the most significant developments on the horizon is the emergence of alternative fiber laser systems that utilize unique gain mediums or different wavelength operations. These systems promise to enhance efficiency and precision in manufacturing processes, tapping into sectors ranging from automotive to aerospace engineering. As industries demand more versatile cutting and welding solutions, these innovative lasers are expected to reduce production times and costs while improving quality.

Another noteworthy trend is the integration of artificial intelligence and machine learning into fiber laser systems. By leveraging data analytics, manufacturers can optimize laser settings in real-time, leading to more streamlined operations and highly individualized production capabilities. This advancement not only enables greater adaptability to specific materials but also enhances the overall user experience by providing smarter, more intuitive control interfaces. The potential impact of these developments suggests a future where fiber laser systems can significantly revolutionize how products are designed and manufactured, driving increased competitiveness in the global market.

© 2025 Messer Cutting Systems, Inc.